Sound Insulation of Buildings

Articles > Sound Insulation of BuildingsThe levels of desired sound insulation, for different types of buildings and between the individual rooms or apartments of a building can be achieved by the following contraction measures of noise control and sound insulation.

Wall Insulation : Vertical Barriers

Walls and partitions are the vertical barriers to noise. Their proper design and construction may insulate the sound to the desired level. Wall construction, used for sound insulation, may be four types.

- Rigid and Massive Homogeneous Walls.

- Partitions of Porous Materials.

- Double Wall Partition.

- Cavity Wall Type Construction.

1. Rigid and Massive Homogeneous Walls

A rigid wall consists of stone, brick or concrete masonry construction, well plastered on one or both the sides. The sound insulation offered by these rigid walls depends upon their weight per unit area. The sound insulation thus increases with the increase in the thickness of the wall. Because of the logarithmic variation between weight and transmission loss, such a construction (i.e.solid wall) becomes highly uneconomical and bulky after certain limit. As can be seen from Table 17.2, the transmission loss (sound insulations) of a one-brick wall is 50 dB while that of a 11/2 brick thick wall is 53. On the other hand, a half brick wall with 13 mm thick plaster on both the sides as TL of 45 dB.

2. Partition walls of Porous Materials

Porous materials may be rigid or non-rigid. Rigid porous materials (such as porous concrete masonry cinder concrete etc.), the insulation increases about 10% higher than the non-porous rigid material. However, partition walls of non-rigid porous materials (such as felt, mineral wool etc.) offer very low sound insulation, though they can be used in combination with rigid materials with added advantage.

3. Double Wall Partition

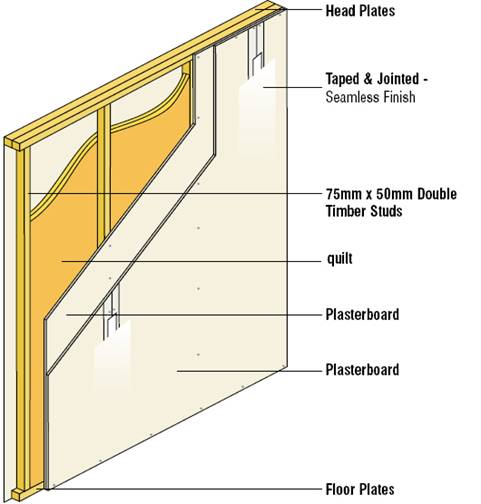

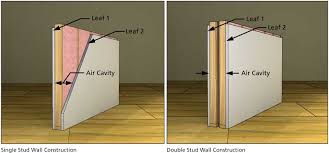

A double wall partition shown in Figure, consists of plaster boards on fibre boards or plaster on laths on both the faces, with sound absorbing blanket in between staggered wooden studs are provided as support, though their number should be a minimum. A double wall construction is thus a partition wall of rigid and non-rigid porous materials.

4. Cavity Wall Construction

This is an ideal construction from the point of view of sound proofing as shown in Figure. The gap between the two leafs of the wall may be left air-filled or else filled with some resilient materials, like quill etc. well suspended in the gap. The two faces of the wall may be fixed with celotex or other insulating board. The width of cavity should be at least 5 cm, and the two wall leaves should be tied by use of only light butterfly wall ties.

Floors

Transmission of sound takes place more easily through floors. This is on account on the fact, that invariably the sound producing source has actual contact with the floor. Hence the floor serves as the most common path for the transmission of impact noise. The ordinary R.C.C. floor weighing less than 220 kg/sqm has a sound reduction of only 45 dB. Thus bare concrete and timber floors do not function effectively as barrier against impact sound. A floating floor resting on a resilient material like glass wool, mineral wool, quilt, hairfelt, corck, rubber etc. has an increased rating for impact sound insulation.

The principle under laying the design of the floating floor is its insulation from any other part of structure. To achieve this, the resilient layer on which the floor rests l's turned up at all edges which about the walls, partitions or other parts of the structure. The partition should be built off the structural floors so that the floating screed is self contained within each room. The various types of floating floor construction are shown in Figure. The wood raft floating floor as shown in Figure consists of 50 mm deep x 50 mm wide wooden battens, on which 20 mm thick resilient quilt is laid over the structural floor slab.

The concrete screed floating floor as shown in Figure consists of a 70 mm thick layer of 1 : 11/2 : 3 concrete screed laid on a 25 mm thick resilient layer of mineral wool quilt. The quilt is covered with waterproof paper to prevent the moisture from concrete screed travelling below on the structural floor slab. Floors with suspended ceilings have an added advantage of insulation against air borne sound, provided a soft floor finish is provided on top to give necessary insulation against impact sound refer Figure.

Wooden Joist Floors

The performance of wooden joist floors is greatly influenced by the amount of indirect or flanking sound, transmitted through the walls. The factor is not important in concrete floors, since the concrete floors are considered heavy, rigid and stiff enough to restrain the vibrations from the walls. In timber floors, this factor can be taken care of by increasing the stiffness and thickness of the wall below the floor. Alternatively, the floor should be made heavy and stiff enough to reduce the vibrations of the walls. The two different types of wooden joist floors which gives adequate sound insulation are shown in Figure.

A note worthy feature in the insulation of these floors is the floating floor effect achieved by using a 25 mm thick mineral wool or glass wool quilt which is dropped over the joist and turned up at the edges of the boards. The efficiency of the flooring system is improved by increasing its weight with Figure plugging between the joints.

Windows and Doors

In case of windows, sound insulation of single windows is improved by making them as air-tight as possible by filling the air space at the edges of such paves with sound absorbing material. Sound insulation or transmission loss further increases in thickness of glass. Excellent sound insulation or sound reduction is obtained by constructing glazed windows with double or triple panes of glass. The air space between two glazing panes should be at least 20 cm wide or 30 cm width is still better. Such windows are especially useful for sound proofing of rooms, such a broadcasting studios etc. In case of doors, the transmission loss or sound reduction increases with the increase in weight. The sound insulation can further be improved by packing the sound absorbing material in the space between the jamb and frame.

Insulating Sanitary Fittings

For improved insulation, water closets should not be fixed above a living room or next to a bed room unless the latter is well insulated as for example by cup-board etc. the W.C. pan and cistern should be insulated. The plan should be made to rest upon a thin pad of felt, linoleum, cork, rubber or other suitable resilient materials. Cisterns should not be fixed directly to a bed-room wall and should be fixe upon insulators fixed to the brackets. The pipe should be properly wrapped, where they pass through walls or floors and be held in insulated clips.

Read also:

Read also:

- Delegating responsibility for roofing work

- All Types of Roofs And Their Details

- Everything About Bricks: Types, Materials, and Construction Methods

- Different Light Weight Construction Technologies

- Typical Interface Friction Angles

Share:

Share:

Follow our official Facebook page (@civilengineeringbible) and Twitter page (@CivilEngBible) and do not miss the best civil engineering tools and articles!