What are the Geosynthetics

Articles > What are the GeosyntheticsIntroduction:

Geo synthetics are artificial fabrics used in conjunction with soil or rock as an integral part of a man-made project. The two major groups in geosynthetics are geotextiles and geomembranes. While geotextile is a permeable fabric, geomembrane is an impermeable one. Stressing permeability, or the lack of it, as the distinguishingfeature, helps to separate the different roles of these two groups of materials. As more products with slight difference has been manufactured and used for different field applications, they are identified by different terms as listed below (John, 1987) :

Geospaceres: impermeable spacers used within fin drains

Geowebs: an American term for cellular geotextiles

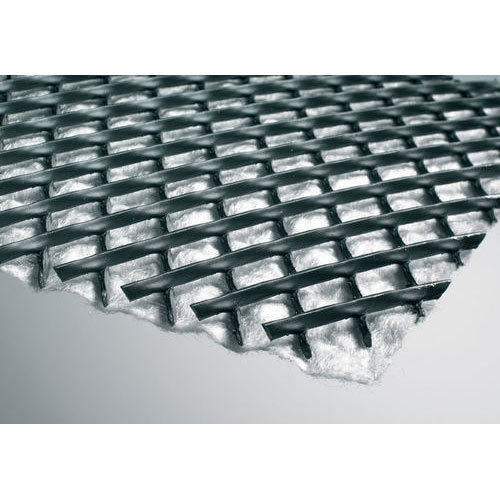

Geogrids: geotextile related products with large rectangular apertures (more correctly called geotextile grids) or non rectangular apertures (more correctly called geotextile nets)

Geosynthetics: geotextiles, geomembranes and geotextile related products, but excluding those based on natural fibres

Geofabrics: planar flat sheet geotextiles and geotextile related products, excluding geotextile mats

Geoproducts: geosynthetics, geotextile related products made from natural fibres, geospacers, and metallic soil reinforcement

Geocomposites : composites consisting of two or more geoproducts.

Geosynthetics have a wide civil engineering field application. The main functionswhich are in use are : (i) separation, (ii) fluid transmission, (iii) reinforcement, (iv) filtration, and (v) containment and barrier. Geosynthetics have been applied on geotechnical and construction engineering for the past 15 to 20 years. Geosynthetics is no longer a new born technology, but is now entering a more mature stage with constantly expanding applications even outside of the traditional construction field.

Geosynthetic Types:

There are a large number of different geosynthetics produced, but for the purposes of classification they can be sub-divided generally into the following groups, viz., Wovens, Non-Wovens, Knitted, Biogradable, Nets and Grids, Three dimensional Mats, Composites and Membranes.

Raw materials:

The raw materials used in the manufacture of geosynthetics are thermoplastics. However, a few specialist geosynthetics may also incorporate either steel wire or natural biodegradable fibres. Examples of biodegradable materials used within geosynthetics are jute, wood shavings, and paper strips. Following is the brief description of the raw materials.

Polyamide: There are two most important types of polyamide (PA). The first one is an aliphatic polyamide obtained by polymerisation of the petroleum derivative s-caprolac- tam. Aliphatic polyamides are composed of chains which do not contain ring-shaped rigid structures. The other type is also an aliphatic polyamide. It is obtained by the polymerisa- tion of a salt of adipic acid and hexamethylenediamine and both of them are petroleum products. They are manufactured in the form of thread or tape which are cut into granules.

Polyester: Polyester (PETP) is made by polymerizing ethylene glycol with dimethyl terephthalate or with terephthalic acid. All these three materials are derivatives of petroleum. Polyster is produced discontinuously in two reactors, in series or in a continuous process using more reactors in series.

Polyethylene: Polyethylene (PE) can be produced in a highly crystalline form, which is an extremely important characteristics in fibre-forming polymer. Three main groups of polyethylene are available, viz.,

Polyethylene: Polyethylene (PE) can be produced in a highly crystalline form, which is an extremely important characteristics in fibre-forming polymer. Three main groups of polyethylene are available, viz.,

LDPE — low density polyethylene (density 920—930 kg/m3)

LLDPE — linear low density polyethylene (density 925—945 kg/m3)

HDPE — high density polyethylene (density 940—960 kg/m3)

LDPE was the first polyethylene developed followed by HDPE. LDPE is produced at very high pressures whereas HDPE processes are initiated by special catalysts at relatively low pressures and temperatures. HDPE is more rigid, stronger, tougher and has a better chemical resistance than the low density types. However, LDPE is used in applications where its flexibility and water vapour barrier properties can be utilized.

LLDPE is a third group of polyethylenes made also by a low pressure process. It is manufactured by co polymerizing ethylene with a small amount of alpha-olefins which lowers the density by forming short chain side branches on the linear polymer chain.

HDPE is preferred for the production of PE filaments and tapes for use in geotextiles whereas LDPE and LLDPE are used more for the production of film. Polythelene is available in granular or powder form.'

Polypropylene: Polypropylene (PP) is a crystalline thermoplastic produced by polymerizing propylene monomers in the presence of a stereo-specific catalyst system. Polypropylene is the highest (900—910 kg/m3) plastic produced to date. Homopolymers and copolymers are the two types of polypropylene. Homopolymers are used for fibre and yarn applications. Polypropylene is mainly available in granular form

Polyvinylchloride: Polyvinylchloride (PVC) is mainly used in geomembranes and as a thermoplastic coating material. The basic raw material utilized for the production of PVC is vinylchloride. PVC is a rigid polymeric material but can be converted, when plasticizers are added, into highly flexible products. PVC is available in free-flowing powder form.

Ethylenecopolymer Bitumen: Ethylenecopolymer bitumen (ECB) membranes have been used in civil engineering works as sealing materials. For ECB production, the raw materials utilized are ethylene and butyl acrylate (together forming 50 to 60%1. and a special bitumen of 40 to 50%. Stricter specifications are required when they are used as a seal in connection with resistance to hydrocarbons, acids and alkalies.

Chlorinated Polyethylene: Sealing membranes based on chlorinated poly- ethylene (CPE), are generally manufactured from CPE, the main component, mixed with PVC or sometimes PE. The properties of CPE depend on the quality of the PE and the degree of chlorination. CPE membranes are available in rolls of a maximum width of 2 m and a thickness in the range of 0.6 to 1.5 mm with a roll length of about 20 m.

Apart from the raw materials explained above there are other polymers also available with less market value.

Wovens

There are a large number of geosynthetics produced which can be sub-divided into several different categories based upon their method of manufacture. They may be basically belong to natural fabrics or synthetic fabrics. Under synthetic fibres they may be broadly classified as conventional geotextiles, geotextile related products and geomembranes.

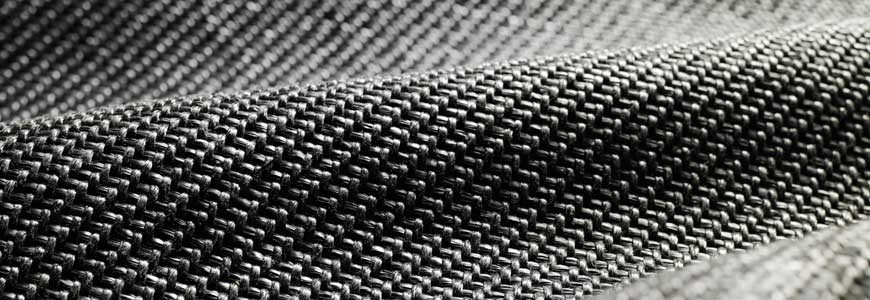

Wovens were the first to be developed from synthetic fibres. The type accounts for about 25% of the geotextiles market in terms of volume. As their name implies, they are manufactured adopting techniques similar to weave clothing textiles. This type has the characteristic appearance of two sets of parallel threads or yarns. The yarn running along the length is known as a warp and the one perpendicular to it is called a waft.

The majority of low to medium strength woven geosynthetics are manufactured from polypropylene which can be in the form of: extruded tape, slit film, monofilament, or multifilament. Often a combination of yarn types is used in warp and waft directions to optimise performance/cost. Higher permeability are obtained with monofilament and multifilament than flat tape construction only.

Non-Wovens

Non-woven geosynthetics can be manufactured from either short staple fibre or continuous filament yarn. The fibres can be bonded together by adopting thermal, chemical or mechanical (needle punched) techniques or a combination of techniques. Whether at staple fibre or a continuous fibre is used has very little influence on the properties of the non-woven geosynthetics.

Read also:

Read also:

- What is Geotechnical Engineering? Subtopics, Salaries, Books, Journals, ...

- Top software for Geotechnical Engineers

- Top resources for Geotechnical Engineers

Share:

Share:

Follow our official Facebook page (@civilengineeringbible) and Twitter page (@CivilEngBible) and do not miss the best civil engineering tools and articles!