historic perspective of special moment frames

Articles > historic perspective of special moment frames

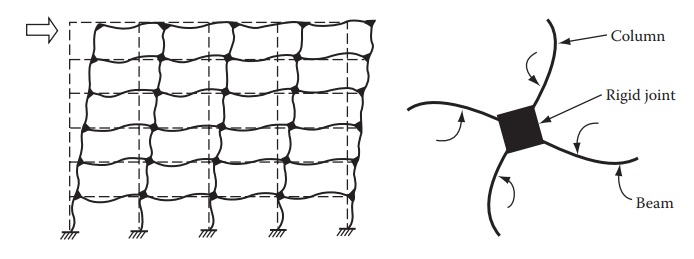

A seismic moment frame comprises of a rectangular system of rigidly connected columns and beams that resist moment and shear forces developed during earthquake ground shaking. Seismic standards typically consider the system extremely ductile and assign it the highest allowable response modifcation coeffcient. It is one of only few systems permitted in SDCs D, E, and F for buildings exceeding 160ft in height.

Because earthquake motions can induce multiple inelastic displacement cycles, special proportioning and qualifcation requirements are essential for robust moment frame performance. Although the steel special moment frame (SMF) is a relatively recent development in building codes, steel frames have been in use for more than 100 years, dating to the earliest use of structural steel in building construction. Framing in these early structures typically utilized “H” shapes built up from plate, “L” and “Z” sections. The connections typically incorporated large stiffened triangular gusset plates, joined to the beams and columns with angles and rivets. The basic construction style remained popular for high-rise construction through the 1930s. By the early 1900s, rolled “H” shape sections began to see increasing use in place of the built-up sections, in particular for lighter framing. Many tall structures including the Empire State Building in New York, for many years the world’s tallest structure, are of this construction type.

Following World War II, engineers began to design connections using unstiffened angles or split tees to connect top and bottom beam flanges to columns. In the 1950s, as welding was introduced into building construction, the angles and split tees were replaced by flange top plates, shop welded to the column flanges, then riveted to the beam flanges. By the 1960s, riveting had become uneconomical and was replaced by high strength bolting. Finally, in the early 1970s, engineers began to use the connection type known today as the welded unreinforced flange-bolted web (WUF-B). Incorporating feld-welded, complete joint penetration groove welds to join beam flanges to columns, and shop-welded, feld-bolted shear plates joining beam webs to columns. Almost from their inception as a means of building construction, engineers began to observe that steel moment frames seemed to exhibit superior performance in earthquakes.

As a result of the apparent superior performance of these structures, building codes of the 1960s adopted preferential design criteria for steel moment frames. Under these codes, buildings having complete vertical load-carrying space frames as their lateral force resisting system could be designed for two thirds of the seismic forces specifed for braced frames and half the forces specifed for bearing wall structures. Further, these codes required such frames in buildings exceeding 240ft in height. In the 1960s and 1970s, researchers began to perform cyclic laboratory testing of steel moment frames. It was determined that some control on proportioning and detailing of these structures was necessary to obtain superior inelastic behavior in strong earthquakes. Throughout the 1970s and 1980s, the building codes began to adopt the recommendations of these researchers and required special design, confguration, and detailing of steel moment frames used for seismic resistance in regions of high seismic risk. Frames conforming to these design criteria were frst designated as ductile moment–resisting space frames, and then fnally in 1988, as special moment-resisting frames. The term “special” was adopted, both because special criteria applied to the design of these structures and also because special, superior behavior was anticipated of them in strong earthquakes.

Initially, the special design criteria were limited to a requirement that connections be capable of developing the strength of the connected members, with the WUF-B connection identifed as a deemed-to-comply standard. Later, requirements were introduced to provide for strong-column weak-beam behavior, balance of the shear strength of panel zones with beam flexural capacity, and addition of section compactness and lateral bracing criteria. Building codes of this era required the use of ductile moment–resisting space frames in all structures exceeding 240 ft in height zones of high risk of experiencing strong ground motion. As a result, nearly every tall building constructed

in the western United States in this era was of steel moment frame construction. Such structures designed in the 1960s and 1970s tended to employ moment-resisting connections at every beam– column joint, providing high redundancy and alternate load paths for distribution of lateral force resistance. However, by the 1980s engineers had begun to economize their designs and minimize expensive feld welding by using fewer bays of moment-resisting framing that employed heavier beams and columns, resulting in less redundant structures with more concentrated lateral force resistance. In extreme cases, some tall structures were provided with only a single bay of momentresisting framing on each side of the building

Following the 1994 Northridge earthquake, engineers were surprised to discover that a number of modern special moment-resisting frame structures had experienced unanticipated brittle fracturing of their welded beam–column connections. Similar damage and even collapse of some buildings occurred 1 year later, in the 1995 Kobe, Japan earthquake. Following these discoveries, a consortium of professional associations and researchers, known as the SAC Joint Venture, engaged in a federally funded, multiyear program of research and development to determine the causes of this unanticipated behavior and to develop recommendations for more robust moment frame construction. It was determined the fractures were a result of the basic connection geometry, lack of control of base materials, the use of weld fller metals with inherent low toughness, uncontrolled deposition rates, inadequate quality control and other factors. The resulting research is the basis for the current steel SMF code design requirements.

Read also:

Read also:

- Types of concentric structural braces

- Empire State Building, New York: All you need to know

- Types of eccentric braced frames

- AISC 341-05 requirements for special plate shear walls

- Steel Quiz (10 Short-Answer Questions)

Share:

Share:

Follow our official Facebook page (@civilengineeringbible) and Twitter page (@CivilEngBible) and do not miss the best civil engineering tools and articles!