Shaft Resistance of Piles

Courses > Foundation Analysis and Design > Bearing Capacity of Piles (Deep Foundations) > Shaft Resistance of Piles Introduction

Introduction

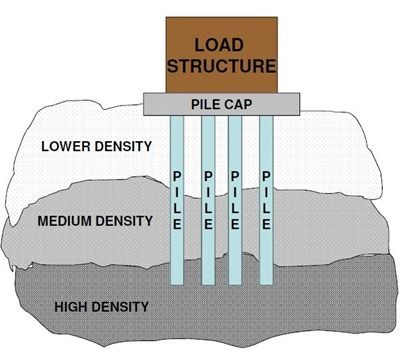

A deep foundation is a type of foundation which transfers building loads to the earth farther down from the surface than a shallow foundation does, to a subsurface layer or a range of depths.

A pile is typically a vertical structural element of a deep foundation, driven or drilled deep into the ground at the building site.

Ultimate bearing capacity of piles is the sum of its skin resistance and tip resistance:

where Q tip,ult = tip resistance; QsL = skin resistance; qtip-ult = bearing stress; Ab = area of pile tip; qsi = skin friction of ith layer; Asi = skin area in contact with ith layer;

Concepts and Formulas

Concepts and Formulas

There are numerous methods that have been used over the years to estimate shaft resistance. A few of these methods are illustrated in this section.

Granular Soils and Drained Clays (Long-term clays):

K-δ Method:

K and δ are usually estimated based on the type of pile and the characteristics of the soil.

Here are some methods to estimate these two parameters.

â–º Estimate K:

1- Stas and Kulhawy method:

| Foundation type and methd of installation | Ratio of horizontal soil stress coefficient to in-situ value, K/K0 |

|---|---|

| Jetted pile | 1/2 to 2/3 |

| Drilled shaft, cast-in-place | 2/3 to 1 |

| Driven pile, small displacement | 3/4 to 5/4 |

| Driven pile, large displacement | 1 to 2 |

2- Sowers method:

| Foundation type | Ratio of horizontal soil stress coefficient to in-situ value, K/K0 | |

|---|---|---|

| Loose sand (Dr < 30%) | Dense sand (Dr > 70%) | |

| Jetted piles | 0.5 to 0.75 | 0.5 to 1.0 |

| Drilled piles | 0.75 to 1.5 | 1 to 2 |

| Driven piles | 2 to 3 | 3 to 4 |

â–º Estimate δ

1- Stas and Kulhawy method:

| Interface materials | Ratio of interface angle of friction to soil angle of friction δ/φ | Typical field analogy |

| sand/rough concrete | 1.0 | cast-in-place |

| sand/smooth concrete | 0.8 to 1.0 | precast |

| sand/rough steel | 0.7 to 0.9 | corrugated |

| sand/smooth steel | 0.5 to 0.7 | coated |

| sand/timber | 0.8 to 0.9 | pressure-treated |

Undrained Saturated Clays (Short-term clays):

alpha method:

obtain α using the following equation from Kulhawy

where Pa = atmospheric pressure; Su = undrained shear strength

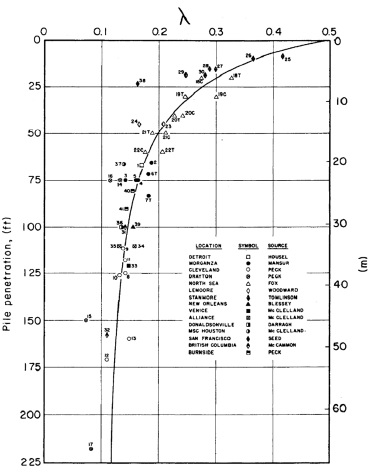

lambda method:

where q is the mean effective vertical stress over the embedded pile length and λ is obtained from the figure below (from Kulhawy). According to Kulhawy, the values of λ shown in the figure below are valid only for steel pipe piles. Limited research has shown that λ for drilled shafts (typically less than 20 ft deep) is on the order of about 1/3 to 2/3 of the values shown in the figure below.

Direct Estimates from In Situ Tests:

From the CPT test, pile shaft resistance can be determined from either the sleeve friction (fs) or the tip resistance (qc):

where ρ is the friction ratio. For driven piles, the value of rho can be estimated from either of the following equations:

or

Values of ρ for drilled shafts are 1/3 to 1/2 the values shown in the two equations above.

Meyerhof recommended the following equations for shaft resistance in high and low

displacement piles:

High displacement piles:

Low displacement piles:

For driven piles in sand, Briaud suggested that:

Watch Videos

Watch Videos

Solved sample problems

Solved sample problems

Download Files

Download Files

Read also

Read also

- Everything about sheet-pile walls: types, materials and construction methods

- Spillways and their types

- Top software for Geotechnical Engineers

- Ultimate Tip Resistance of Piles

- Anchored Sheet Pile Walls Penetrating Sandy Soils

Share

Share

Follow our official Facebook page (@civilengineeringbible) and Twitter page (@CivilEngBible) and do not miss the best civil engineering tools and articles!